Some of the printing producing any manufactured goods can be an extensive, complex, and classy process connecting many examinations and errors. The procedure includes designing, picture, testing, varying, correcting, redesigning, etc. A lot of employment has to go into just right any part before mass produces it. This is where prototyping can supply an enormous deal. By produce, machining, or manufacture a prototype, one can create an incomplete representation, test and appraise it and make the required transform and amendment to it, all before launching construction. Prototyping is grave for verification of the product design and its congregation.

The prototyping progression allows for the unearthing of errors in the early step so that that redesign can acquire a place to just the product. It brings good organization to the development and saves companies an enormous deal of time and financial statement, especially in suitcases where rigid timeline or imperfect budget has occupied.

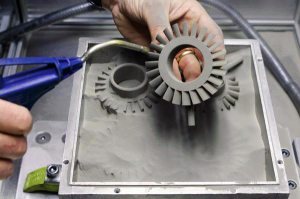

At present, many companies are turning to 3d printing metal powder which is an enormous solution to make the prototype, especially in an occurrence where the prototyping model requirements to be very specific or customized to correct details. 3D printing knowledge is also acknowledged as additive industrialization has become more and more accepted in recent years. The parts construct in the 3D printer are fashioned directly from the intended file. This means that we can avoid the time and cost of tooling and be intelligent to change the device digitally and fashion updated prototypes in less time, helping budge to the production and developed process faster. Besides, the 3D printer should use multiple pieces of equipment at the same time to construct the prototype. Every people have to fulfill their products while doing their work.

Part of printing

When generating the part with the 3D printer, we can see the representation or prototype, touch, and examine it. What we have in our hands is a physical taster of our end-product. We can produce it from the same or comparable materials to the complete product. Most people can then test our product under exacting requirements and environment, such as survive wind, heat, water, coatings, paints, etc. The testing phase is decisive to construct the compulsory tweaking and upgrading of the product as desired, ensuring that what we have is a superior product. We cannot do that if all we have is a CAD design on our computer, and it is hard to envisage it even if we are using 3D files.

In recent years 3D imprinter has become quicker, more comfortable to utilize, and handle multiple pieces of equipment simultaneously, thus more accepted. They can generate prototypes in continuous industries, including engineering manufacturing, automotive, aerospace, resistance, pharmaceutical, medical, dental and health care, sports, art, building, hobby models, customer goods and electronics, and many more. Not only is 3D printing fiscally and time-wise positive, but its production process initiates a more natural way of generating the product – Not a lot of fragment material which requirements to be used is involved. The opportunity of creative development and development now lies in the hands of those reform high-technology imprinter.